AI/ML Enabled by HPC for Edge Camera Devices for Next Generation Poultry Farms

THE PROBLEM/CHALLENGE

Monitoring chickens on large farms is highly labour-intensive and costly, and as representatives from poultry industry noticed may hinder the productivity of staff members for other tasks. Raising chicken to ensure animal well-being as well as humane food production means to closely monitor environmental conditions: measuring air temperature, air humidity, CO2, and ammonia levels are required as a basis for successful production. Having insights into chicken body temperature, behaviour, and growth, provides the possibility of undertaking adequate measures on time. Companies DigitalSmart and DunavNET gathered around the question of how to utilize AI and ML to develop computer vision sensors that can monitor the aforementioned parameters. This can be achieved with the help of cameras installed on poultry farms and edge AI devices with integrated ML prediction models. However, training, selecting, and calibrating the prediction models that can be ported onto edge AI devices using only a standard computer was extremely slow, tedious, and therefore not feasible without access to HPC.

SOLUTION:

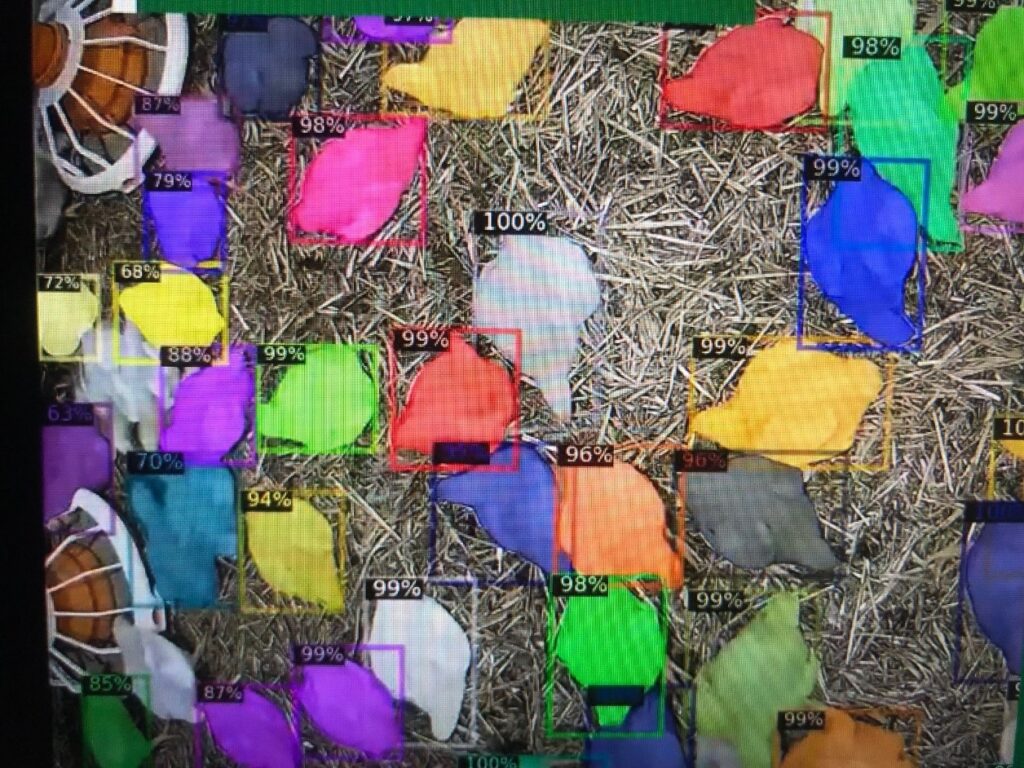

Example of the object (chicken) detection and instance segmentation

In order to help farmers accomplish this, DunavNET addressed the monitoring of poultry on large farms with a modern digital farming platform based on the Internet of Things (IoT) technology. Artificial intelligence and machine learning algorithms were used to create prediction models such as counting chickens, detecting dead chickens, and estimating their weight and size, which could indicate the appearance of certain diseases. HPC is used to efficiently apply deep learning to train and later calibrate these prediction models. This process led to the creation of a new type of precision agriculture sensor that combines cameras, edge computing, and an IoT platform in order to support the next generation of poultry farms. HPC provided a crucial, over 10-fold improvement in time savings for the development of custom prediction models. This improvement is pivotal because models are calibrated for specific end-users and achieve an accuracy of over 90% for chicken detection and segmentation. These models are subsequently ported into edge IoT devices equipped with camera sensors. Such IoT devices, enhanced with edge AI capabilities and new prediction models, represent new building blocks for advanced smart agriculture solutions for the poultry industry.

BENEFITS:

- Much faster (minutes vs hours/days) detection of disease or abnormalities leads to improved animal well-being and better agro-food product quality (flock uniformity improvement; chicken stress elimination; real growth tracking; weight measurement accuracy) and also lower greenhouse gas emissions by optimizing production condition, dead chicken detection and carcass disposals.

- Results permit the chicken farms to reduce both manual labour costs and chicken mortality rate by 10%, saving hundreds of thousands of Euros annually.

- HPC is enhancing competitiveness and innovation potential of SME in the commercial poultry sector. HPC provided the technology SMEs tools needed to develop smart agriculture solutions quickly and efficiently by using machine learning and computer vision for the needs of the poultry industry. The computer kit has become a part of the PoultryNET platform offering, and there is an opportunity to sell such components to third-party vendors active in the market of smart agriculture solutions.

The project was featured in FF4EurHPC success stories booklet [link].